I. Introduction

Compressor in the current industrial plant is very widely used, according to the different compression medium, the compressor can be divided into a variety of air compressor is the most common one, air compressor as an important power equipment is widely used in machinery manufacturing, chemical industry, cement and building materials, mines, power plants, transport construction and many other fields, and this paper introduces the compressor is mainly used to compress the natural gas through the compression of natural gas boosterThe compressor is mainly used to compress natural gas, through the compression and boosting of natural gas, the compressed natural gas is used to refuel the car, and the 250KW 8-pole asynchronous motor is used to compress the natural gas by dragging the 250KW 8-pole asynchronous motor with a 280KW frequency converter of E-Drive CV3100 series.

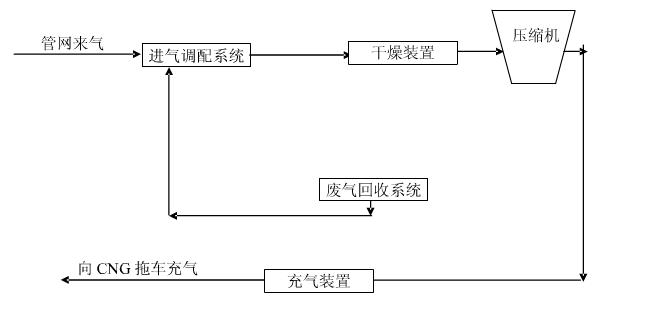

II. Workflow

Filling process: get the gas source from the pipeline network, gas distribution, separation, buffer, metering of natural gas into the station, need to be equipped with gas valves, regulators, flow meters, intake separation and filtration of buffer tanks, after the drying system will be the natural gas in the depth of the water through the molecular sieve removal, to ensure that the finished product of the leakage point of the gas to meet the requirements of the next drying of the collateral natural gas into the compressor to increase the pressure to 24MPa, will have been boostedNext, the dry mortgaged natural gas into the compressor pressurisation to 24MPa, will have been pressurised, dehydration of the finished gas in order of priority to the car direct charging or respectively to the high, medium and low pressure storage tanks for gas supply, to achieve not only energy saving but also ensure that the pressure of the high-pressure storage system for the purpose of gas recovery system for the recovery of gas station leakage of natural gas, in order to save and protect the environment.

Four ﹑ on-site commissioning analysis

The beginning of the customer reflects the machine on the power to run for a period of time to show ER09 fault, fault current 1000A or so, after arriving at the scene, let the customer run the machine machine in the process of running does appear ER09 fault, fault current and the customer reflected in line with the fault after observing the customer found to be the external PLC programme has a problem in the machine running for some time after the PLC programme!Error issued a stop command, when the frequency converter in the process of running down, and the customer's deceleration time is set to 10S (too short), resulting in the machine in the process of running down suddenly received a stop signal shutdown, due to the customer in the process of stopping the deceleration time is too short, the mechanical inertia is large, which led to the emergence of the ER09 failure to the machine's stopping process into a free stopping the machine in the process of receiving external PLC's stop command, the machine is not a free stop.PLC's stop command, the machine automatically stops, there is no ER09 fault, then the machine equipment with pressure to start, the compressor pipeline inside the pressure of nearly 40 kilograms or so, resulting in the start of the machine jumped ER09 fault, the machine fault current of 980A, fault frequency of 6.32HZ, modify the machine's P0.16 for the 3, start the machine, the machine fault remains, the fault frequency of 6.16HZ, fault current of 6.16HZ, fault frequency of 6.16HZ, fault frequency of 6.16HZ, fault frequency of 6.16HZ.6.16HZ, fault current 1004A, try to modify the P0.17 for 10, run the machine, fault frequency 5.89HZ, fault current 1106A, then continue to try a variety of V / F curve parameter settings, in the start-up still back to the ER09 fault, and finally tried the vector control method, the input of the machine's current, speed and other related parameters to the frequency converter, so that the machineSelf-study, run the machine more than 10 times, the machine no longer appear ER09 fault, monitor the machine's current maximum between 600 - 700A momentary fluctuations, the machine debugging success.

*** Translated with www.DeepL.com/Translator (free version) ***

五﹑现场应用情况

六﹑总结

通过使用变频器以后压缩机的启动电流减小,加载时的电流平缓上升,没有任何冲击;同时输出的压力稳定,提高生产效率和产品质量;以后设备的维护量减小,压缩机启动电流小,小于2倍额定电流,加卸载阀无须反复动作,节能控制柜控制压缩机根据用气量自动调节电机转速,运行频率低,转速慢,轴承磨损小,设备使用寿命延长,维护工作量变小;与之同时,变频器具有欠压、过流、过载、过热,缺相等保护功能,使机器运行可靠平稳。

六﹑总结

通过使用变频器以后压缩机的启动电流减小,加载时的电流平缓上升,没有任何冲击;同时输出的压力稳定,提高生产效率和产品质量;以后设备的维护量减小,压缩机启动电流小,小于2倍额定电流,加卸载阀无须反复动作,节能控制柜控制压缩机根据用气量自动调节电机转速,运行频率低,转速慢,轴承磨损小,设备使用寿命延长,维护工作量变小;与之同时,变频器具有欠压、过流、过载、过热,缺相等保护功能,使机器运行可靠平稳。

-

Easy drive GT200 series frequency converter in the music fountain application

Easy drive GT200 series frequency converter in the music fountain application2025-04-16

Learn more

-

Application of GT200 series inverter in calendering and slitting integrated machine

Application of GT200 series inverter in calendering and slitting integrated machine2025-04-16

Learn more

-

Application of GT200 series products on sheet extruders

Application of GT200 series products on sheet extruders2025-04-16

Learn more

-

Application of GT200 inverter in direct feed drawing machine

Application of GT200 inverter in direct feed drawing machine2025-04-16

Learn more

Get the latest industry solutions and case studies

Contact us by phone, email to solve your problems