Equipment Introduction

Wire drawing machine is an important equipment for the production of metal wire, mainly to draw metal wire into a variety of specifications of fine wire.Common wire drawing machine: water tank type wire drawing machine, straight into the type of wire drawing machine, wheel-sliding type wire drawing machine and so on.

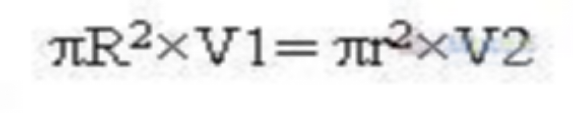

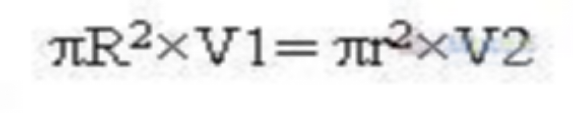

Straight into the wire drawing machine is a small continuous production equipment consisting of a number of drawing head, through the drawing of each level, can be a one-time cold drawing of steel wire to the required specifications, so the work efficiency is relatively high.However, due to the wire diameter changes after each level of drawing, so each drawing head working speed should also change.According to the different configuration of the drawing mould, the drawing speed of each drawing head should also be changed.Drawing speed of the benchmark is each moment through the pulling die of the wire of the second flow volume is constant, even if the following formula is established:

Where R: diameter of the incoming wire

r: the diameter of the outlet wire

V1: the wire speed of the incoming wire

V2: the line speed of the wire out of the wire

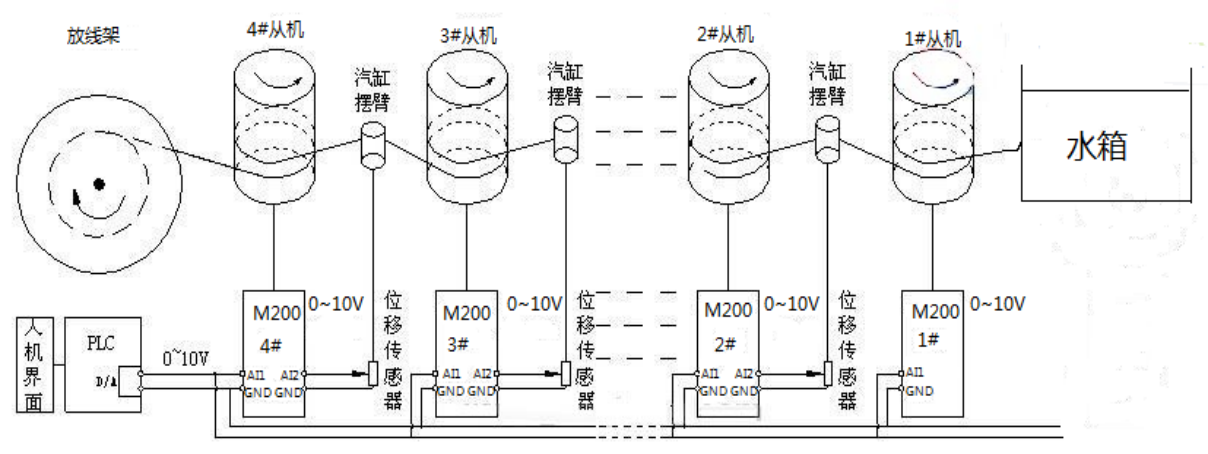

In theory, we can maintain the steady state of the system through the transmission ratio.However, in the actual operation process, due to the mechanical transmission error and in the process of starting, accelerating, decelerating and so on at all levels of error, resulting in the pulling head can not be kept in sync, so we designed the use of easy to drive GT200 frequency converter + displacement sensors of the programme. GT200 frequency converter through the sampling of displacement sensors of the feedback signal, to automatically adjust the frequency converter running speed, so as to achieve the system synchronizationsteady state operation.

The direct feed wire drawing machine includes: a water tank drawing, 4 (or more) slaves, and only one start button and one stop button to be pressed throughout the work.Achieve a high degree of automation of the equipment, greatly saving labour.

The requirements of the frequency converter

1. The inverter is required to have good low-frequency torque characteristics and large starting torque.

2. PID response quickly to ensure that the whole system works smoothly in a synchronous state.

3. The frequency converter has the function of line break detection, when the line is broken, it will automatically give the line break signal, so that the whole system can be shut down quickly.

4. Each level of slave, when the cylinder arm in front of it is not tensioned, there is no action when starting or stepping on the point of action until it is tensioned and synchronised.

III. Advantages of the GT200

1. The software adopts advanced current space vector algorithm, and the hardware adopts international advanced DSP chip to ensure the stable and reliable work of the inverter.

2. Improve the traditional PID algorithm, trip unique direct-entry wire drawing machine dedicated PID response algorithm to ensure that the system does not break the wire in the process of starting, stopping, accelerating and decelerating.

3. Relying on the special PID algorithm, the PID operation process is further processed to ensure that each slave in the case of its predecessor cylinder arm is not tensioned, start the system or point the system, the slave does not move.When the cylinder arm is tightened, the slave responds quickly, without breaking or loosening the wire.

4.GT200 is specially designed to deal with broken wire, without adding hardware such as travel switches, automatically judge broken wire, no omission, no false alarms.

IV.Frequency converter parameter debugging

Generally speaking, the special programme for direct-entry wire drawing machine does not need debugging parameters, and its parameters are all built-in, so customers only need to be wired according to the diagram, which is greatly convenient for customers.

Transmitter mode: the displacement sensor sensing surface close to the metal, the feedback analogue signal is weaker, and vice versa, the stronger.When debugging, according to the cam surface and sensor sensing surface of the change rule, select the transmitter mode.

V.Daily maintenance

1. Regularly check whether the sensor is fixed firmly, whether the feedback signal of the sensor is within 0~10V.

2. Due to the working environment of the wire drawing machine is relatively harsh, regular cleaning of the inverter control cabinet to ensure that no foreign objects into the inverter, to ensure that the inverter good heat dissipation.

-

Easy drive GT200 series frequency converter in the music fountain application

Easy drive GT200 series frequency converter in the music fountain application2025-04-16

Learn more

-

Application of GT200 series inverter in calendering and slitting integrated machine

Application of GT200 series inverter in calendering and slitting integrated machine2025-04-16

Learn more

-

Application of GT200 series products on sheet extruders

Application of GT200 series products on sheet extruders2025-04-16

Learn more

-

Application of GT200 inverter in direct feed drawing machine

Application of GT200 inverter in direct feed drawing machine2025-04-16

Learn more

Get the latest industry solutions and case studies

Contact us by phone, email to solve your problems