Application of Easy Drive CV3100 Series Frequency Converter in Compressor

- Categories:Electric power

- Author:

- Origin:

- Time of issue:2020-07-06 12:02

- Views:

(Summary description)After using the inverter, the starting current of the compressor is reduced, and the current during loading rises smoothly without any impact; at the same time, the output pressure is stable

Application of Easy Drive CV3100 Series Frequency Converter in Compressor

(Summary description)After using the inverter, the starting current of the compressor is reduced, and the current during loading rises smoothly without any impact; at the same time, the output pressure is stable

- Categories:Electric power

- Author:

- Origin:

- Time of issue:2020-07-06 12:02

- Views:

Information

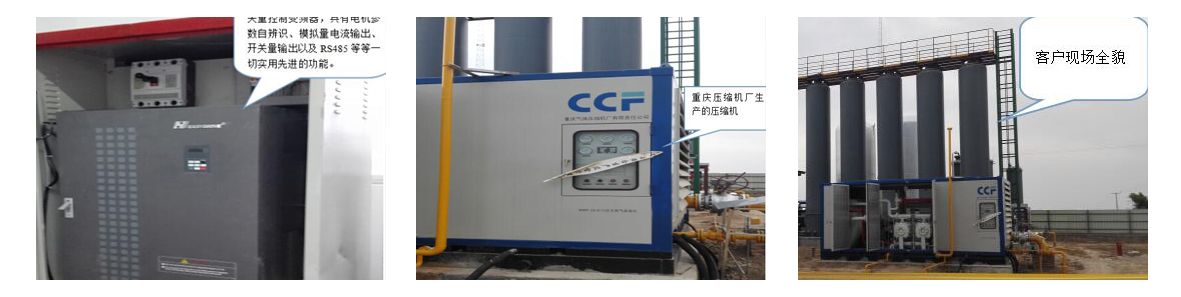

I. Overview

Compressors are widely used in current industrial plants. According to the different compression media, compressors can be divided into many types. Air compressors are the most common type. As an important power equipment, air compressors are widely used in machinery manufacturing and chemical engineering. , Cement and building materials, mines, power plants, transportation construction and many other fields, and the compressor introduced in this article is mainly used to compress natural gas. The natural gas is compressed and pressurized by the compressor, and the natural gas is sent to thousands of households, using the easy drive CV3100 -4T2800M series high-performance inverter drives the compressor, which can realize the smooth start of the compressor and the function of stepless speed regulation. At the same time, the built-in PID closed-loop system of the easy-drive inverter can monitor the system pressure at any time to ensure the stability of the system pressure. To drive the application of CV3100-4T2800M frequency converter in the compressor of gas station, the motor is a 250KW 2-pole motor.

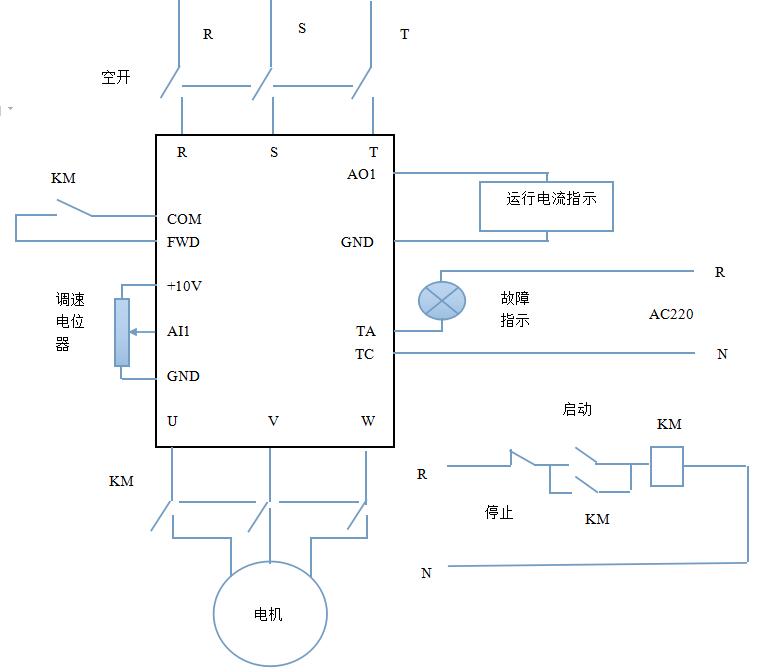

2. Field application circuit diagram

5. Summary

After using the inverter, the starting current of the compressor is reduced, and the current during loading rises smoothly without any impact; at the same time, the output pressure is stable, and the pressure of the gas in the gas supply pipeline can be kept constant through the PID of the inverter to improve production Efficiency and product quality; the maintenance of the equipment will be reduced in the future, the compressor starting current is small, less than 2 times the rated current, the loading and unloading valve does not need to be repeatedly operated, the energy-saving control cabinet controls the compressor to automatically adjust the motor speed according to the gas consumption, and the operating frequency is low. The speed is slow, the bearing wear is small, the service life of the equipment is prolonged, and the maintenance workload is reduced. At the same time, the inverter has the protection functions of undervoltage, overcurrent, overload, overheating, and lack of equalization, so that the machine runs reliably and smoothly.

Scan the QR code to read on your phone

Related News.