The reform plan of easy drive frequency converter in central air conditioner

- Categories:HVAC

- Author:

- Origin:

- Time of issue:2020-06-22 17:48

- Views:

(Summary description)With the development of the national economy and the improvement of people’s living standards, central air-conditioning systems have been widely used in hotels, hotels, office buildings, shopping malls, hospital buildings, industrial plants and other occasions.

The reform plan of easy drive frequency converter in central air conditioner

(Summary description)With the development of the national economy and the improvement of people’s living standards, central air-conditioning systems have been widely used in hotels, hotels, office buildings, shopping malls, hospital buildings, industrial plants and other occasions.

- Categories:HVAC

- Author:

- Origin:

- Time of issue:2020-06-22 17:48

- Views:

Information

I. Introduction

With the development of the national economy and the improvement of people’s living standards, central air-conditioning systems have been widely used in hotels, hotels, office buildings, shopping malls, hospital buildings, industrial plants and other occasions. The system structure consists of refrigeration compressor units and cold (heat) medium circulation. Water system, cooling circulating water system, cooling tower fan system, coil fan system, etc. The system design capacity is mostly selected in accordance with the building's maximum cooling, heating load or fresh air exchange demand, and there is a large margin. In the process of use, it is impossible to adjust with the changes of seasons, day and night, and the number of people. The motor runs at full speed at the power frequency for a long time, and the phenomenon of "big horse-drawn trolley" appears. Although the system uses gate valves and baffle throttling methods, energy waste is very serious. Electricity consumption accounts for more than 60% of the total electricity consumption of the building. Among them, water pumps account for about 40% of the total electricity consumption of the air conditioning system. So there is a lot of energy saving space. Therefore, saving the power consumption of the main compressor system, water pump, and fan system at low load has extremely important economic significance.

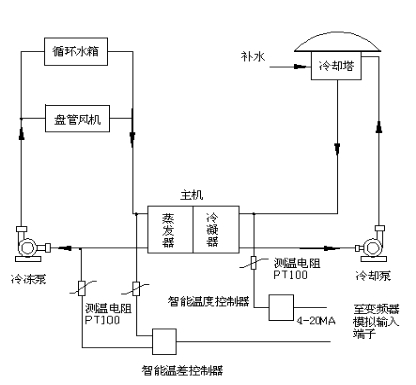

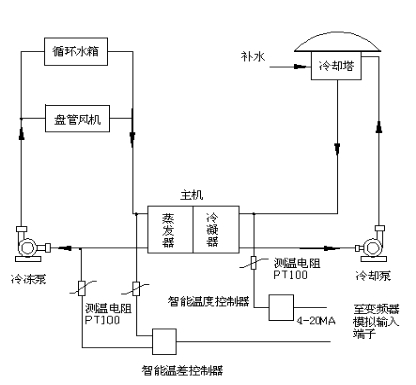

2. The working principle and scheme design of the central air-conditioning system

It is composed of the main engine, chilled water circulation system, and cooling water circulation part. As shown below:

Central air conditioning systems can be divided into two categories according to load types:

Constant torque load: For example, the compressor of screw type or centrifugal refrigeration main compressor system not only has the minimum requirement for the torque output by the shaft, but also the relationship between the speed and power is approximately linear.

Square torque load: such as cooling circulating water system, refrigerating circulating water system (heat pump circulating water system), cooling tower fan system, coil fan system and other fans, water pump loads, they do not have strict requirements for shaft torque, The shaft power and speed have a significant cubic relationship. Different load types have different torque and power relationship characteristics, and energy saving space is different.

2.1 Energy-saving regulation principle of refrigeration compressor

Take the vapor compression refrigeration cycle as an example, the refrigeration cycle process of the refrigeration system of the central air-conditioning is shown in Figure 1. The power adjustment of the screw compressor can be achieved by means of frequency conversion adjustment to reduce the rotation speed of the screw. (In order to prevent the occurrence of backflow of high-pressure gas formed from the exhaust end to the exhaust hole, such as fuel injection, the minimum exhaust volume is usually limited to about 10%). Therefore, the power output of the screw compressor can be steplessly adjusted in the range of 10% to 100%. Empirical data shows that when the load of the screw compressor is above 50%, its power is linearly proportional to the load, and when the load is less than 40%, its actual power consumption is much greater than the calculated power of linear theory, so the full load cannot be achieved when using variable frequency technology The ideal energy-saving effect is obtained in the interval, which troubles the application of frequency conversion control technology. From the above analysis, it can be seen that as far as the central air-conditioning refrigeration compressor is concerned, the compressor itself has adopted an automatic adjustment method, and it is generally not recommended to carry out energy-saving transformation of the refrigeration compressor.

2.2 Energy-saving regulation principle of fan and water pump

Energy-saving theory basis

According to the theory of fluid mechanics, the output flow Q of centrifugal fluid transmission equipment (such as centrifugal water pumps, fans, etc.) is proportional to its speed n; output pressure P (head) is proportional to the square of its speed n; output power N and its speed n Is proportional to the third power of, and can be expressed as:

Q ∝ n

P ∝ n2

N ∝ n3

It can be seen from the above principle that reducing the speed of the water pump can reduce the output power of the water pump even more. Before transformation, we need to judge whether the system has energy saving potential. Due to the particularity of the central air-conditioning system, it is mainly considered from two aspects: first, the rated flow and head index of the pump itself and the actual output performance during operation; second, the temperature difference required by the system for the actual water supply demand, or The size of the deviation between the pressure and the standard index of the unit. Take refrigerating pump as an example, adopt real-time collection of inlet and outlet water temperature data, through intelligent temperature controller to control calculation processing, output 4-20MA analog signal, and determine the adjustment direction and adjustment range of the inverter to the pump. In order to avoid the phenomenon of "stuffy pump" or "cut-off", the speed of the pump should be limited above a certain value. This lower limit speed (minimum supply head and flow) can be set by the lower limit frequency of the output of the inverter to ensure sufficient Under the premise of head and flow (to avoid the low-pressure detection and alarm action of the central air-conditioning system), it is recommended to use temperature control to achieve this.

2.3 Closed-loop control of the refrigerating medium water pump system (detecting the temperature difference between inlet and outlet water)

The standard inlet and outlet temperature of refrigerated circulating water in the central air-conditioning system is 12°C/7°C, and the allowable temperature difference between the standard inlet and outlet water of the rated index condenser is 5°C. For example, the temperature difference between the inlet and outlet water is 2°C, so from the perspective of temperature difference, the actual demand for refrigerated circulating water is only 2°C/5°C=40% of the supply. In the case of variable frequency speed control, the actual speed of the pump only needs to work 40% of the rated speed can meet the requirements, and the energy consumption of the pump is only about 10% or less of the rated energy consumption. The insufficient energy exchange causes the cooling effect of the system to deteriorate, so the energy saving space is very large. Under the condition of ensuring the chilled water flow supply of the most terminal equipment, determine the minimum operating frequency of a chilled pump inverter (generally 25HZ), set it as the lower limit frequency, lock the lowest operating speed of the chilled water pump, and use intelligent temperature control The controller detects the temperature difference between the inlet and outlet of the refrigerated water to control the frequency increase or decrease control mode of the inverter, so that the frequency of the refrigerated return water is higher than the set temperature and the frequency is increased steplessly.

2.4 Closed-loop control of chilled water pump system in heating mode (detection of inlet and outlet, water temperature difference)

This mode is the same as the control scheme of the chilled water pump system when the heat pump is running in the central air conditioner (autumn and winter).

2.5 Open loop control of cooling circulating water pump (detection of inlet and outlet, water temperature difference)

The standard cooling cycle inlet and outlet water temperature difference of the central air-conditioning system is: 4℃~8℃, the standard cooling tower temperature difference between the inlet and outlet water temperature is: 3℃~5℃, and the hot water inlet and outlet temperature for heating is: 50℃/60℃. This part is composed of cooling pump, cooling water tower and condenser. While the chilled water circulation system performs indoor heat exchange, it also takes away a large amount of indoor heat energy. The energy is transferred from the refrigerant in the host to the condenser to increase the temperature of the cooling water; the cooling pump transports the heated cooling water to the cooling water tower (water outlet ) To exchange energy with the atmosphere, cool down and send it back to the main condenser (return water). Therefore, the cooling water circulation system is affected by both the outdoor environment temperature and the indoor heat load. The water temperature on one side of the circulating water pipe cannot accurately reflect the heat exchange capacity of the system. It is necessary to install a temperature difference sensor on the inlet and outlet main pipes of the cooling pipe, as shown in Figure 1. It is a reasonable energy-saving method to use the temperature difference between the outlet water and the return water as the basis for controlling the indoor temperature. When the external environment temperature is constant, the temperature difference is large, indicating that the indoor heat load is large. The speed of the cooling pump should be increased, and the speed of the cooling water circulation should be increased; correspondingly, if the temperature difference is small, the speed of the cooling pump will be reduced. The energy-saving space is about 5-10% larger than that of a single measurement of the return water temperature.

It is precisely because of the excess effect of pressure and flow that the water flow is too fast and the heat exchange temperature difference is small. Therefore, it is possible to approach the standard temperature difference reference value by reducing the total supply flow of heat pump circulating water, thereby saving energy. Therefore, when investigating the actual operating conditions, one cannot simply judge based on the size of the motor's operating current. If you simply look at the actual operating current of the motor in the refrigerant circulating water system, there will be an error that there is not much room for energy saving. judgment. Therefore, it should be based on the actual operating point data: such as system equipment capacity selection, different seasons, different time load changes and other factors, the actual central air-conditioning system is basically not consistent with the standard indicators. In most systems, there are phenomena such as small temperature difference, high head, and excessive flow. The use of frequency conversion speed regulation technology can save the excess flow and head of the system, so that the system can work under the best energy consumption conditions (head Under the condition that there is no excess of flow and flow), so as to meet the needs of the system and minimize the energy consumption.

2.6 Coil fan system control

According to your company's introduction, the coil fan is 11kw, and the maximum air supply temperature difference of the coil fan is: 10℃~15℃ (generally the temperature difference between the inlet and outlet of the air is 8℃). The coil fan system is a system that uses water and air as the load heat transfer medium in the plant at the same time, but most of the main indoor cold and heat loads are borne by the refrigerant water or heating medium water in the coil. Meet the hygienic ventilation requirements of the plant to improve the comfort of the plant, and only bear part of the cooling or heating load.

After the implementation of the variable air volume transformation, the temperature of the factory room can be stably controlled at 17°C±1°C, especially in winter, which is equivalent to about 40% of its rated power compared with the power frequency consumption.

2.7 Cooling tower fan control

Analysis of the current situation of the cooling tower fan system (generally two fans per set), the original control method adopts the power frequency full speed operation under the direct start mode. Both cooling tower fans are running at full speed. The system lacks effective cooling effect detection and does not make full use of the opportunity to save electricity under natural cooling. This results in two extreme states of cooling tower fans: either running at full speed or manually stopping, especially In spring, autumn, and winter, manual operation cannot respond to changes in the cooling tower outlet water temperature in time to start and stop the fans, resulting in a huge waste of energy due to operation and management. During the transformation, each set of cooling towers is implemented with the inlet water temperature of 35°C as the fan's initial operating point, 30°C as the stop operating point, and the temperature range of 35°C to 30°C as the basis for fan frequency adjustment, and the implementation of temperature PID variable air volume adjust. After actual operation test, the energy consumption under the variable air volume control mode is only about 30% of the power frequency start-stop control mode, and the variable air volume control completely avoids the manual start-stop power frequency operation mode, because the operation has no real-time performance or management Energy waste caused by imperfections. According to the statistical data of a large number of typical cases of energy-saving transformation of central air-conditioning system, after the successful energy-saving transformation of central air-conditioning system is realized, the energy-saving rate of the cooling tower fan system is above 30%. Some of them contain large-capacity cooling tower reservoirs. The cooling tower system can reach more than 40%.

1. Take a cooling pump, a refrigeration pump and a makeup pump with a power of 22KW as an example:

A. Operating current is 38A, and variable frequency current is 26A. Then the shaft power of the motor is:

P axis 1=UIcosφ=×380V×38A×0.85=21.2KW

P axis 2=UIcosφ=×380V×26A×0.85=15KW

Power saving rate=(21.2-15.0)/21.2×100%=29%

Due to the difference of the power supply voltage in different places, the current may be different, so the power saving rate is between 25% and 40%.

Taking into account the actual production downtime and the maintenance and repair downtime, it is now calculated based on 300 days a year and 24 hours a day.

Power saving=1×6.2KW×24×300=44640KWh

The annual average electricity bill is 0.8 yuan/kWh, and the electricity savings are as follows:

44640×0.8=35712 (yuan)

2.11KW coil fan

A. Operating current is 19A, and variable frequency current is 12.7A. Then the shaft power of the motor is:

P axis 1=UI1cosφ=×380V×19×0.85=10.6KW

P axis 2=UI2cosφ=×380V×12.7A×0.85=7KW

The power saving rate = (10.6-7)/10.6×100%=34%

Due to the difference of the power supply voltage in different places, the current may be different, so the power saving rate is between 25% and 40%.

Now it runs for 300 days a year (in fact, there are not so many days) and runs 24 hours a day. Then

Power saving=1×3.6KW×24×300=25920KWH

The annual average electricity bill is 0.8 yuan/kWh, and the electricity savings are as follows:

25920×0.8=20736 (yuan)

2.8 Advantages after transformation

(1) Since the current cooling water circulating pump is operating at full power frequency, in the early and late stages of the refrigeration cycle, the ambient temperature is lower and the cooling water return temperature is lower, which will cause lithium bromide to crystallize, resulting in a reduction in the efficiency of the air conditioning unit, and even protection. After adopting variable frequency constant temperature difference control, the return water temperature is effectively controlled, which will greatly improve the efficiency of the air conditioning unit and achieve the purpose of energy saving.

(2) Since the chilled water circulating pump is also operating at full power frequency and cannot automatically adjust the flow rate according to the requirements of the indoor temperature, the refrigeration pump can automatically adjust the flow rate according to the outdoor temperature and indoor temperature requirements after the frequency conversion transformation, which improves the efficiency and achieves Energy saving purpose.

(3) Reduce the impact on the power supply and system when the air conditioner is turned on and off

Reduce the impact of the air conditioner on/off on the power grid. Due to the large power of the circulating water pump, when the power frequency starts/stops the pump, the impact on the power grid is greater, affecting the operation of other equipment. After adopting frequency conversion control, the water pump realizes soft start and soft stop, and its current is less than the rated current, which no longer has an impact on the power grid.

Reduce the water sag effect of the circulating water when the pump is stopped. Because it is a frequency conversion soft stop, and the process of stopping the pump can be controlled, it can completely eliminate the water sag effect when the pump is stopped, and eliminate the impact of the water sag on the air conditioning system pipe network.

(4) Reduce equipment failure rate

After adopting frequency conversion control, the circulating water pump works below the rated power most of the time, which will effectively reduce the failure rate of the equipment and reduce the repair and maintenance of the equipment.

(5) Improve the automation of equipment

Realize the overload and over-current protection of the circulating pump. Automatically control the temperature of the cooling water and chilled water of the chiller to ensure the safe and efficient operation of the unit.

In summary, the use of frequency conversion control for the circulating water pump of the central air conditioner has obvious economic benefits, and it is very necessary to carry out frequency conversion transformation of the system.

Three, the characteristics of easy drive inverter

1. The inverter interface is LED display, with rich monitoring parameters; the keyboard layout is simple and easy to operate;

2. The temperature/temperature difference sensor is a digital dual-screen LED display, which is convenient for setting temperature parameters and easy to monitor;

3. The frequency converter has a variety of electronic protection devices such as overcurrent, overload, overvoltage, overheating, etc., and has a wealth of fault alarm output functions, which can effectively protect the normal operation of the water supply system;

4. After the inverter is installed, the motor has soft start and stepless speed regulation functions, which can greatly reduce the mechanical wear of the water pump and the motor, and extend the life of the pipe group;

5. The system realizes PID closed-loop adjustment of temperature, and the indoor temperature changes smoothly, which greatly improves comfort

Fourth, the conclusion

At present, the market for energy-saving technological transformation projects of central air-conditioning systems is not only widely distributed, but also large in number, which lays the foundation for the promotion of market-oriented application of energy-saving transformation. According to statistics, at least 70% of the central air-conditioning systems that have been put into operation have not undergone any energy-saving transformation, and they have good energy-saving space. The application of frequency conversion technology to the central air-conditioning system is of great significance for improving the automation level of central air-conditioning, reducing energy consumption, reducing the impact on the power grid, and extending the service life of machinery and pipe networks.

Scan the QR code to read on your phone

Previous:

None

Previous:

None

Related News.