Application of Easy Drive ED3100 Series Inverter on Roots Blower in Chemical Industry

- Categories:HVAC

- Author:

- Origin:

- Time of issue:2020-06-22 17:31

- Views:

(Summary description)This article introduces the application of Easydrive frequency converter on Roots blower, discusses the control system and functional requirements of Roots blower and the superior performance of ED3100 series frequency converter on Roots blower.

Application of Easy Drive ED3100 Series Inverter on Roots Blower in Chemical Industry

(Summary description)This article introduces the application of Easydrive frequency converter on Roots blower, discusses the control system and functional requirements of Roots blower and the superior performance of ED3100 series frequency converter on Roots blower.

- Categories:HVAC

- Author:

- Origin:

- Time of issue:2020-06-22 17:31

- Views:

Information

Summary:

This article introduces the application of Easydrive frequency converter on Roots blower, discusses the control system and functional requirements of Roots blower and the superior performance of ED3100 series frequency converter on Roots blower.

1 Introduction

Roots blower, which is widely used in various industries of the national economy, is an increasingly important position, and is a universal air source equipment. The chemical, cement, and steel industries are the three most important application industries for Roots blowers. In recent years, with the introduction of domestic industry optimization and upgrading, energy conservation and emission reduction policies, the implementation and promotion of backward elimination, equipment upgrades and other policies, new opportunities have emerged in the traditional market, and the use of frequency conversion transformation of Roots blowers has become more and more widespread.

2. Production process

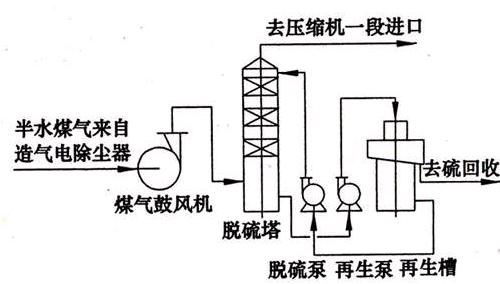

The Roots blower used in the chemical desulfurization blower is a rotary positive displacement blower. Its blowing volume is proportional to the fan speed, and is basically not affected by the change in the resistance of the air outlet. According to the previous control method, this hard wind characteristic determines that it is not allowed to pass The method of closing the air outlet or the air inlet to adjust the air volume, and after optimizing the above main process steps, a large amount of excess air volume can only be adjusted by bypass, which causes a large loss of fan energy, and the problem of corrosion due to wear is prominent. Bypass The valve needs frequent maintenance. The process flow equipment diagram is as follows:

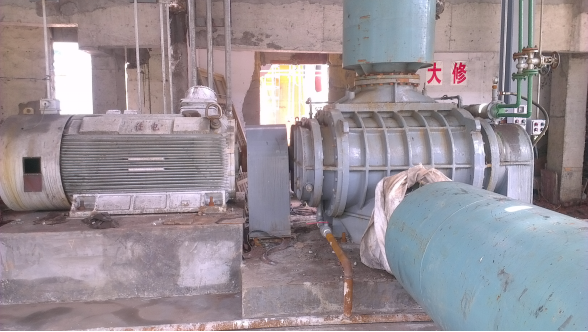

3. Site plan

The inverter is equipped with an automatic bypass cabinet, which can be automatically (or manually) switched between the variable frequency state and the industrial frequency state through the control of the intermediate relay. In the frequency conversion state, KM3 is closed and KM4 is disconnected, and the inverter controls the motor; in the power frequency state, KM3 is disconnected and KM4 is closed, and the motor is switched to the power frequency band. The inverter can automatically switch the power frequency operation in the event of a serious fault, which not only ensures the normal operation of the inverter, but also avoids the impact of the large current of the motor directly on the power grid. The frequency conversion wiring diagram is as follows:

5. Advantages of using easy drive inverter

According to the frequency conversion implementation plan for this project and the practical results of other similar projects, it is concluded that the use of easy drive frequency converter has the following advantages:

(1) Simple installation. The inverter is installed between the low-voltage switch cabinet and the motor, and the wiring is relatively simple.

(2) Simple operation. Intuitive DCS software interface, the system software has operations such as startup, shutdown, frequency adjustment and monitoring status.

(3) Smooth speed regulation. It can carry out stepless speed regulation, wide speed regulation range, and high speed regulation accuracy.

(5) Power saving is obvious. According to the requirements of working conditions, the inverter generally runs at about 40Hz, and the actual output current is less than half of the rated current, which has a significant power saving effect.

(6) Noise reduction. Since the motor runs at a lower speed, the operating noise is greatly reduced, and the heat generation of the motor is also significantly reduced.

6. Conclusion

Judging from the on-site operation, the ED3100 series inverter produced by Shenzhen Yiqi Electric Co., Ltd. has superior performance, reliable operation, and effectively reduces production costs. Today, when the cost of production materials is increasing, effective energy-saving transformation has obvious advantages. Economic benefits.

Scan the QR code to read on your phone

Related News.